Also Read

Sheet Metal Introduction

Sheet metal is simply metal formed into thin and flat pieces. It is one of the fundamental forms used in metalworking, and can be cut and bent into a variety of different shapes. Countless everyday objects are constructed of the material. Thicknesses can vary significantly, although extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate.

Uses of Sheet metal:-

For making buckets, duct, pans, Gutters, tanks, boxes, food containers, dairy equipments, cans, radiators in automobiles, chemical plants, and domestic heating appliances, construction of airplanes, Refrigerators, house hold utensils and fabrication work for making bus bodies etc,. by using various metals like Galvanized iron(GI), Black iron, Tin plate, Stainless steel, Copper, Aluminum etc,..

Sheet metal Tools Required:-

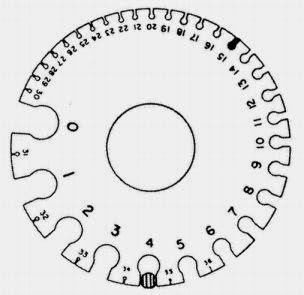

Plate gauge:-

Used for measure thickness of sheets.

The most commonly used gauge in sheet metal has 21 slots with gauge numbers ranging from 4 to 24.

Steel rule:-

Used for taking linear measurement. The accuracy is 0.5mm in metric and 1/64 inch in British system.

Flexible push pull rule:-

Used for measuring long dimensions. Generally the maximum length of the role is 10meters

Scriber :-

Used when we draw marking lines on metal surface.

Divider:-

It is used for transferring the sizes.Scribing curves, Circles on a sheet metal with small raids.

Trammel points:-

Used for drawing very large circles and arcs on sheet metal surface.

Steel square(Try square):-

Used for accurate laying out work. For marking dimensions perpendicular to any base.

Semi circular protractor:-

Used for setting bevels, transferring angles. The indicating arm of the blade has line graduations for accurately setting and reading the protractor.

Punch:-

Made with tool steel. The point and head is hardened and tempered. Shank is knurled to provide grip.The point angle is 60 degrees to 90 degrees.Used to punch dotted lines on sheet metal.

Mallet:-

Used whenever light blows are required.

Riveting hammer :-

Used for forming rivet heads

Raising hammer:-

Used for making depressions with a flat chisel.Used for removing small marks or indentations from the job surface. To true the shape of the work and to smoothen finished work

Comments